Bakery Shortening-Margarine

Bakery Shortening-Margarine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 2 Units Per Year

- Delivery Time

- 1 Months

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Middle East, South America, Asia, Central America

- Main Domestic Market

- All India

About Bakery Shortening-Margarine

With years of experience and deep insight of the field, we bring to you our Bakery Shortening-Margarine that is used in various bakeries in order to make delicious puff pastry and biscuits. It works by preventing the cross linking of gluten molecules and thus preventing elasticity of the dough. It helps in lessening elasticity of margarine which is helpful in making cakes and other pastries. Further, the flexible pipe arrangement of our Bakery Shortening-Margarine makes it suitable for various other applications.

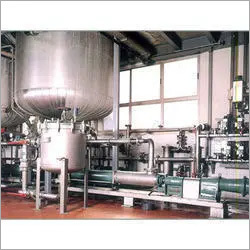

Sparktech supplier of process equipment now presents Bakery Shortening Plant for processing bakery shortening. The capacity is dependent upon product formulations and inlet temperature of the product to be processed.

The Plant Consists of The Following:

- Essess Processor-Heat transfer cylinder assembly.

- Crystal distribution cum stabilizer.

- Triplex plunger reciprocating pump.

- Nitrogen gas purging system.

- Interconnecting product pipeline.

- Control panel.

- Two numbers of interconnected Ess Processor consisting of a single horizontal heat transfer cylinder assembly mounted on an open frame. The cylinder is jacketed and lagged for use with glycol solution. The removable heat transfer cylinder will be internally hard chrome plated. The Essess Processor shaft is concentrically mounted within the cylinder and has four diametrically opposed rows of floating type scraper blades and is driven by suitable motor hose proof to IP55 standard via belts and pulleys suitably guarded.

- All the products contact parts are made of stainless steel AISI 304 materials. The scraping blades, seal parts and '0' rings will be compatible with the product. The frame and external product non-contact parts are in carbon steel and finished painted with metallic paint.

- Two number of heaters are provided for heating of the product in case of product solidification inside the product cylinder during a power failure or production stoppage.

- The esses processor chilling jacket is suitable insulted for eliminating heat loss and cladded with stainless steel sheets for maintaining utmost hygiene.

Flow Sheet For Vanaspati Plant With Nitrogenation/ Votator Section

|

Sr. No. |

DESCRIPTION |

Qty |

Sr. No. |

DESCRIPTION |

Qty |

|

1 |

CHURN TANK |

1 |

7 |

CRYSTALISER |

1 |

|

2 |

GEARED PUMP - 1 |

1 |

|

|

|

|

3 |

BLENDING TANK - 1,2 |

2 |

|

|

|

|

4 |

GEARED PUMP - 2 |

1 |

|

|

|

|

5 |

2-CYLENDER |

1 |

|

|

|

|

6 |

VOTATER-1,2 |

2 |

|

|

|

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese